Press

Leading the development of protocol on garbage bin

From: 2020-07-07 To: 2020-07-07

Region: Zhongshan

From left to right: Chairman of Guangdong Plastic Society, Zhongshan L.K. General Manager, Zhongshan L.K. Senior engineer, Guangdong Plastic Society secretary.

Zhongshan L.K. leading the development of such protocol

The Guangdong Plastic Society and the Standards Institute of Plastic Industry in Guangdong have recently granted the status of major drafting unit to Zhongshan L.K. on (T/GDPIA3-2019), with Zhongshan L.K. General Manager being the major drafter.

In 2019, the Ministry of Housing and Urban-Rural Development listed 46 major cities, including Beijing, Shanghai, Guangzhou and Ningbo, as places for testing grounds for waste sorting, with some cities mandated the classification as a legal requirement. The demand for outdoor large size garbage bins has increased accordingly and the standardization of equipment producing such bins are also listed on the agenda.

To standardize the requirements on the injection molding machines for outdoor large size garbage bins, Zhongshan L.K. has participated in the standardization committee and spearheaded in the drafting of such protocol.

Such protocol listed out the terminology, definition, specs, testing methods, inspection rules, labels, packaging, transportation and storage of such machines.

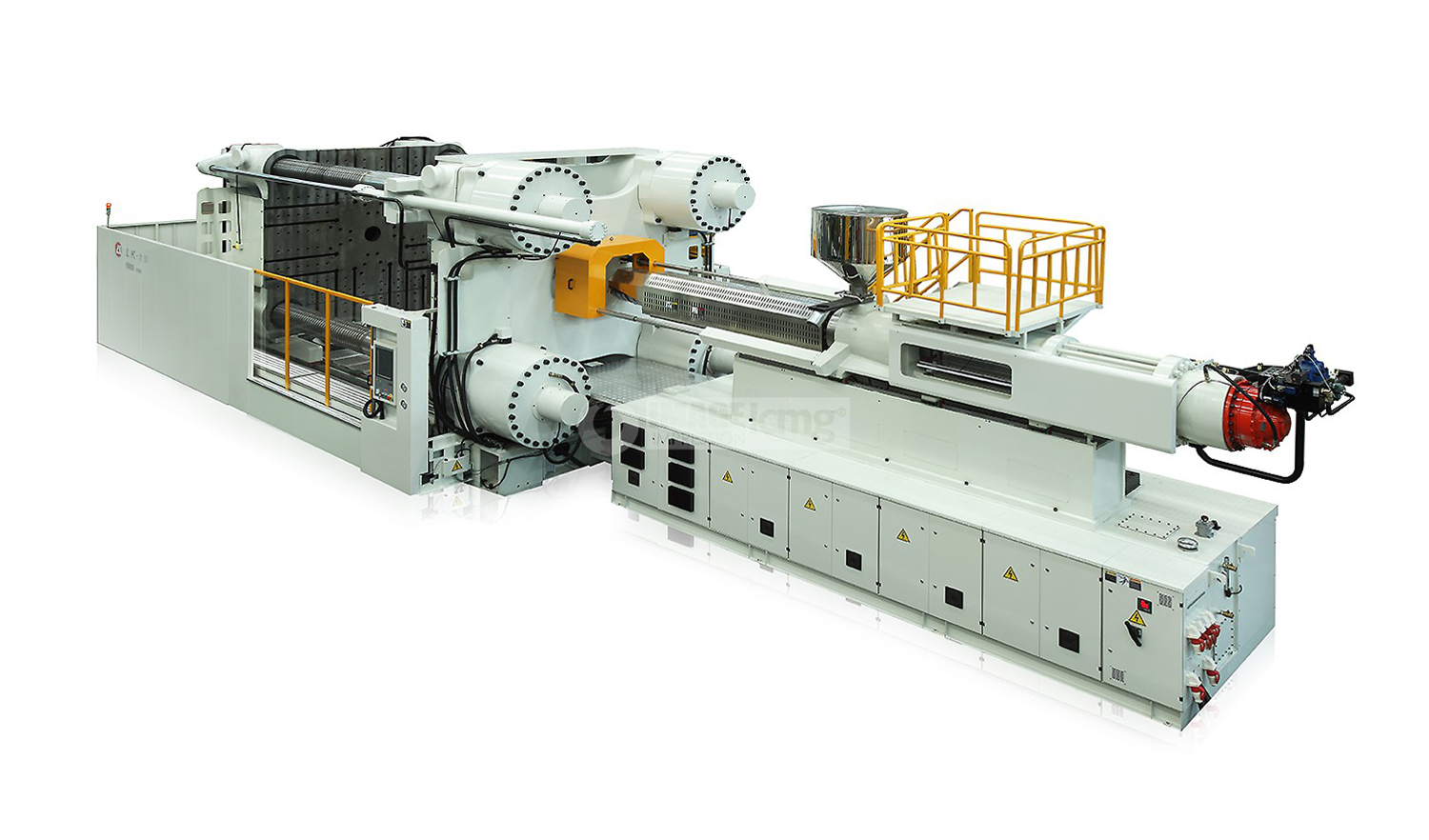

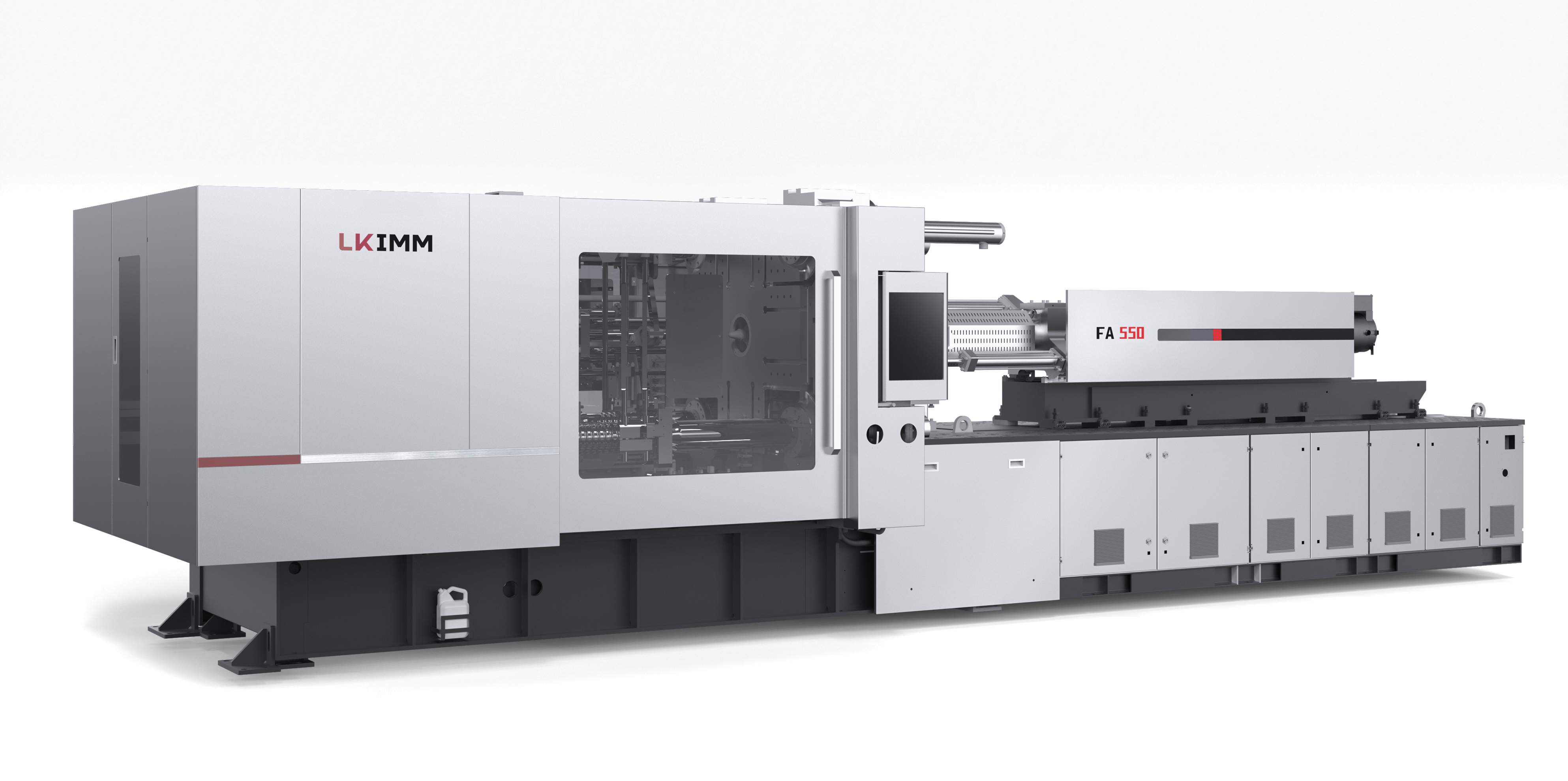

Actual use of LK Forza-III two-platen garbage bin machine at customer’s site

As one of China’s top 5 injection molding machine manufacturer, the LK Forza-III 2-platen machine designed for garbage bin manufacturing is well received, with products achieving quality standards and certifications.

LK Forza-III two-platen machine has an extra-large shot weight and mold opening stroke, and it has an advantage in manufacturing large size garbage bins and septic tanks. The ejector on the fly function and plasticizing parallel with mold open function is standard on the machine, and they are beneficial for production efficiency.

Outdoor garbage bins are typically made on recycled material and with additives, resulting in below-average flow index. As a result, LK engineers equip the machine with specific screws and barrel to ensure the melting, flow and blending with colorants for product quality. With the peripherals for automation, the high production efficiency and high volume mass production requirements can be fulfilled.

“The cavity for garbage bins is longer than average products, and thus the injection molding machine needs to have a 2x opening stroke than traditional injection molding machines. The traditional way was to use big tonnage machines to manufacture small garbage bins and the ROI was quite high. Our Forza-III machine has the advantage of producing garbage bins because our opening stroke is 2x that of traditional machines, and the machine is specifically tailored to fit into garbage bin manufacturing.” said LK engineer.