Press

Die casting solutions for 5G optical modules, enlightening 5G telecommunications

From: 2020-06-06 To: 2020-06-06

Region: China

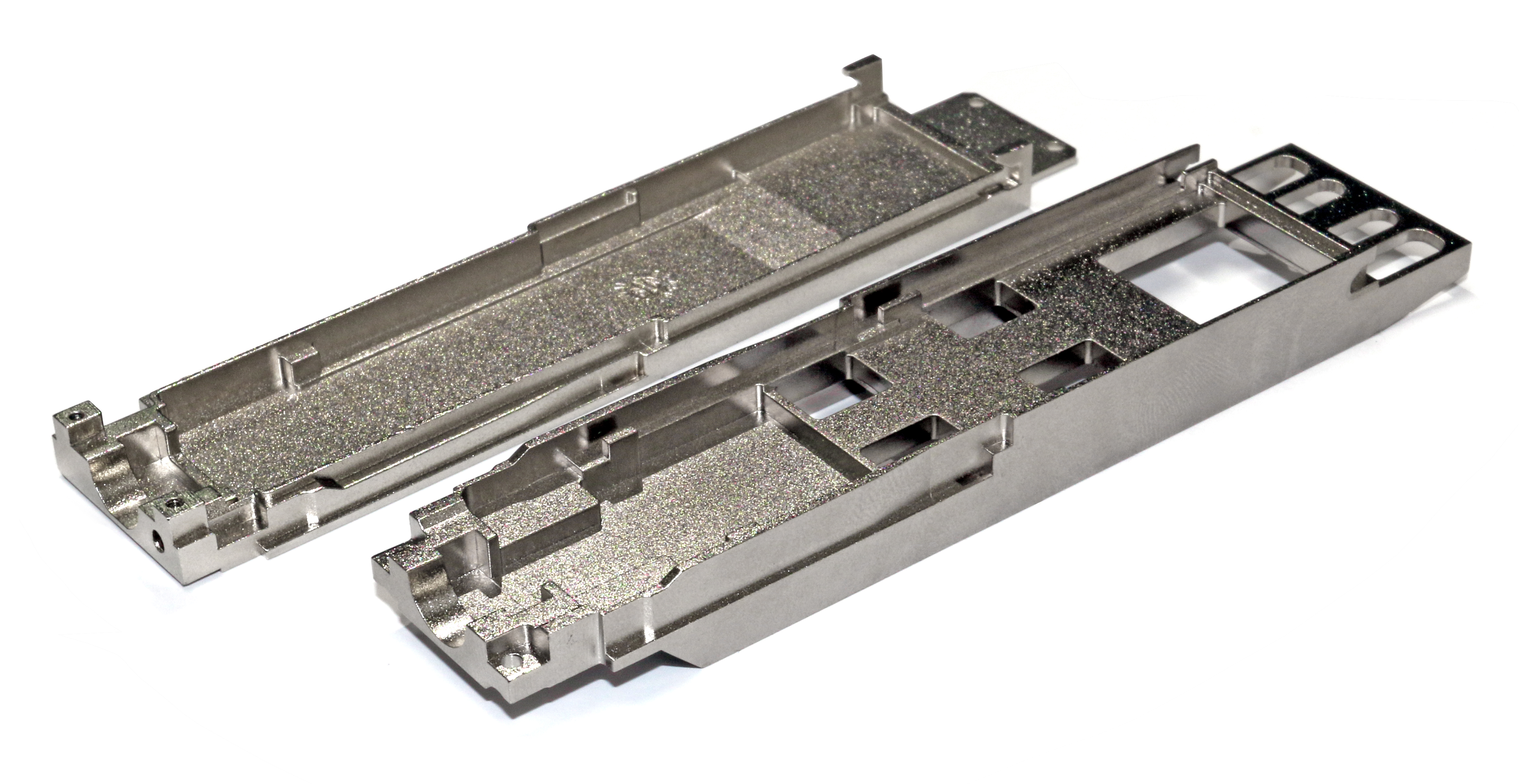

Optical modules are optical transceiver that are widely used in telecommunications industry. The emergence of 5G sparked a new development trend in optical modules.

Optical modules are tiny and delicate, with a complicated design and with high requirements on the surface. The demand for optical modules is growing exponentially. The mass production rate and high surface quality are some of the requirements when purchasing die casting equipment.

Die casting solutions for 5G optical modules

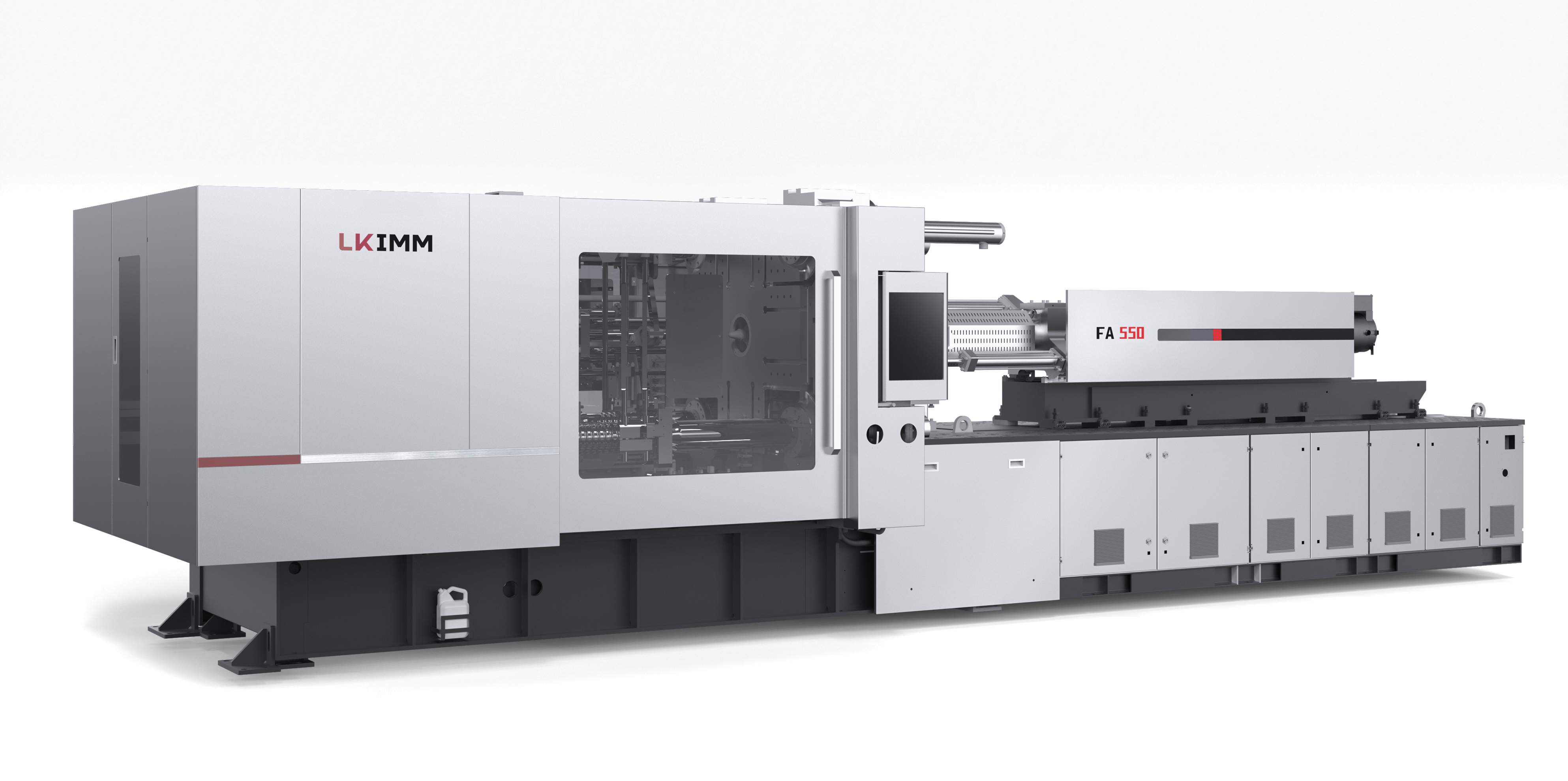

The first AVIS series hot chamber die casting machine was launched in 1994. Throughout the years, there has been various AVIS versions and improvements. Particularly, the AVIS-II DC88 hot chamber die casting machine has become the machine well suited for manufacturing optical modules.

Excellent product formation

Precision in injection pressure and weight and also the excessive runner and porosity problem is bring to a minimal.

Mass production

The max. injection speed can achieve 4.8 m/s. Different die configurations enable multiple products to be produced in a cycle (1/4/8, etc). When equipped with automation for extraction and spraying, each shift (assume 12 hrs) can manufacture ~5000 products.

High efficiency servo motor

The servo motor is able to achieve >40% energy saving. The machine has a characteristic of having quick response, closed-loop control on system pressure and flow, and high precision on repeating motion.

Quick delivery

We are able to achiever short lead time, effectively fulfilling customers' requests quickly.

Integrated equipment with interconnectivity.

Different pieces of equipment can be integrated and interconnected together, achieving synergy in production. Multiple production lines can be equipeed with central material delivery system.

There are several options for this machine, including smart cra