Press

The magnificent 40 years and the story of Mr. Liu and LK (2nd part)

From: 2020-01-12 To: 2020-01-12

Region: China

How LK is related to the die casting and the automotive industry

40 years of Chinese Economic Reform and LK is on the same pace as China

1979 marks the beginning of the Chinese Economic Reform. China has developed rapidly for the past 40 years. Nowadays, China has become a great power as it is the second largest economy in the world. On the same year as China started the economic reform, Mr. Liu founded LK in Hong Kong, focusing on making die casting machines and components.

"In the 70s and 80s (of last century), China was still undeveloped, with little growth in industry. It was difficult for us to find machine component companies, and those companies were mainly focused on the military, with little participation from the civilians. It was not until the Chinese government announced the policy that gradually shifted from military-based economy to civilian-based economy that the civilian market started to grow." Said Mr. Liu.

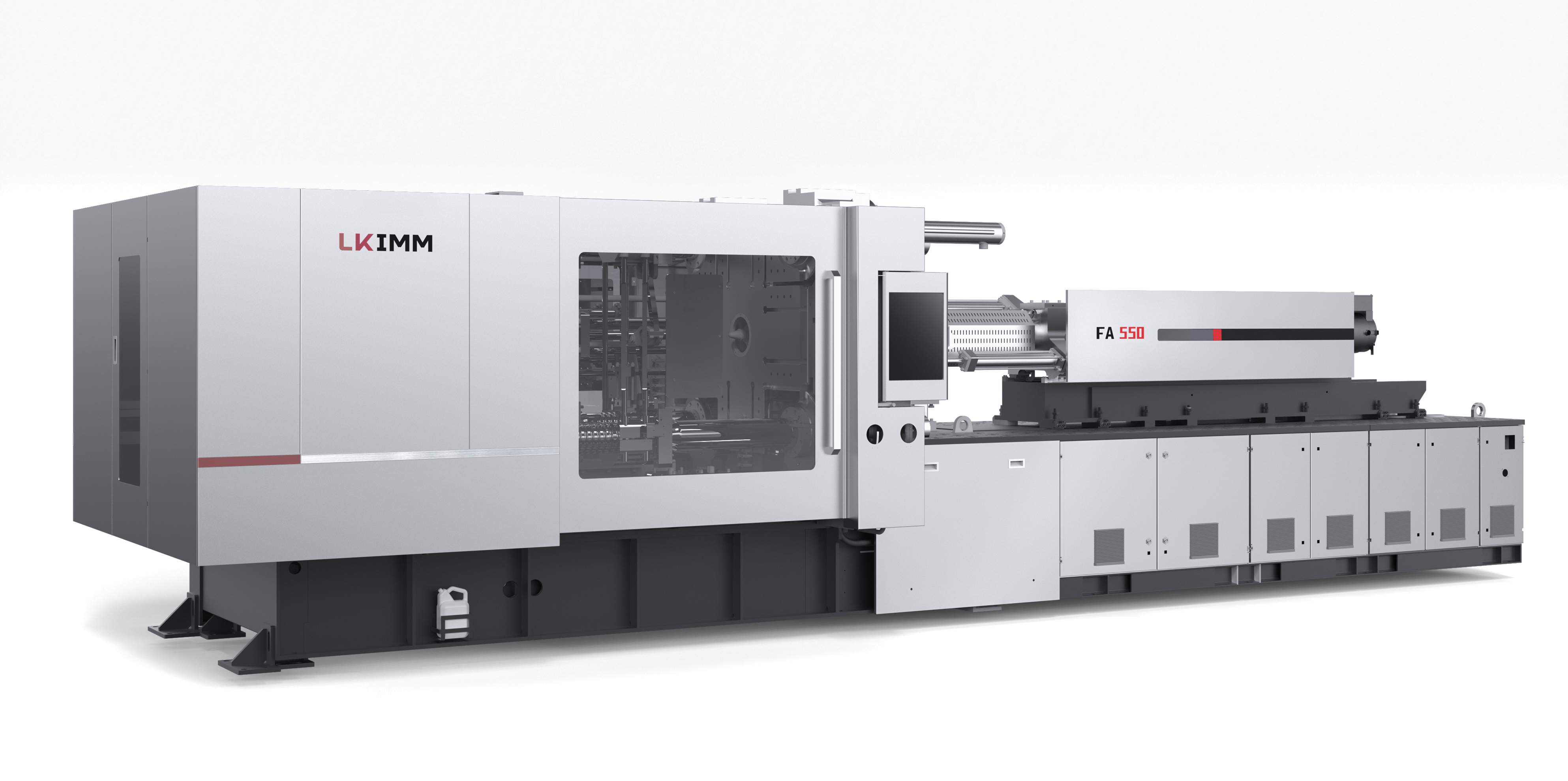

In the past 40 years China has seen tremendous growth and changes and has made a great leap forward. It took China only 40 years to accomplish what other countries took 100 years to achieve. At the same time, LK grew from a small workshop to a multi-million dollar conglomerate, and was successfully listed on the main board of the Hong Kong Stock Exchange. LK produces die casting machines, plastic injection molding machines and CNC machining centers, and has coverage throughout the world thanks to the 10 manufacturing plants in China, Taiwan and Italy.

Mr. Liu said, "There were already advanced die casting and injection molding factories in Hong Kong and Southeast Asia in the 80s. When I paid a visit to a die casting factory in the US in the 90s, I saw huge assembly lines in the workshop. During that time I was thinking ‘How many years would it take for us to be on the same level as them".

Time elapsed and now we are in the 21st century. However, the level of craftsmanship and the scale of die casting in Southeast Asia remain the same as they were in the 90s. Due to factors such as slow technical advancement and escalating manufacturing cost, a lot of the die casting factories had changed to trading companies that trade die casting components from China.

On the other hand, at the General Motors Arlington Assembly in Arlington, Texas, there are 21 sets of 3000T die casting machines of LK running 24/7. The workshop started the renovation in 2008 and that finished in 2011 and phased out 42 sets of local die casting units. The plant is under steady production.

40 years ago, China produced a measly 60,000 tons of die casting parts. In 2018, that figure saw a 100x grow to 6 million tons. Nowadays, there is no single part that a Chinese company cannot make. Not only is the production volume biggest in the world, but its craftsmanship and technology level is on par with developed countries in Europe and North America.

LK and the growth of the automotive and motorcycle industry in China

40 years of development in China has made LK grow from a small workshop into a multi-million dollar conglomerate. Mr. Liu said, “During the 80s, customers were mainly looking for small consumer products, and they were from hot chamber machines. At that time, the case of the watch was mainly imported. After the release of LK hot chamber machines, a large of customers emerged and they focused on making products such as watch cases and belt knuckles.

In the 90s, the automotive and motorcycle industry in China started to emerge and die casting industry saw unprecedented growth. Mr. Liu said, “The demand for die casting machines for the motorcycle industry has spurred a great opportunity for us that, by developing die casting machines specializing in the motorcycle industry, we were able to acquire 80% of the market share.”

Entering the 21st century, the motorcycle and automotive industry continued to grow. “In the past, the engine block and the transmission case for some car models cannot be made locally. The automakers had to procure from outside and finish the assembly here.” Said Mr. Liu. “We saw the trend of those parts being manufactured locally, and thus we launched cold chamber die casting machines tailored for producing those parts, and the machines were well received by the customers."

The production volume data of the automotive and motorcycle industry proved what Mr. Liu said to be true. The production volume for motorcycles is 49 thousand for 1980, 0.966 million for 1990, 11.53 million for 2000 and 26.694 million for 2010. The figure peaked in 2011 for 27.002 million, and started to drop to 15.578 million for 2018, respectively. The Golden Age for motorcycle manufacturing is between the 1990s and 2010s.

On the other hand, the production volume for automobiles is 0.22 million for 1980, 0.509 million for 1990, 2.07 million for 2000, 18.654 million for 2010, 29.015 for 2017 and 27.899 million for 2018, respectively. The time when the production volume saw the biggest growth was between 2000 and 2010.

Mr. Liu said, “We are honor to be part of the Chinese Economic Reform. We grow together with the growth of the automotive and motorcycle industry and we strive to deliver the best solution to customers.”

Development in the automotive industry to bring development to LK

Although the application of die casting parts is more widely used than before, the automotive industry is still leading the development of the die casting industry as a whole. The production volume of cars in China saw a decline in 2018 and 2019 after reaching its peak in 2017. The automotive industry in China has now come to a period of stagnation.

However, Mr. Liu still believes that the production volume of cars and the demand for die casting parts will be growing steadily. He said, “The number of cars in China is estimated to be 300 million, and the time of ownership of a car is estimated to be 10 years. Based on this calculation, China needs to get 30 million cars each year. Second, different automakers are raising their production volumes in China. For example, Toyota made 1.6 million cars in China in 2019 and they are aiming to raise it to 3.5 million. There are also expansion plans for Germany automakers. What we can say from those is that different automakers are still seeing the bright future of automotive production in China.

Mr. Liu said, “The automotive industry will continue to affect eh die casting industry, especially for new energy vehicles. The development of new energy vehicles will accelerate due to stringent emissions regulations in China and other parts of the world.” He predicted that the production volume of new energy vehicle in China will account for 50% of the total automotive production volume.

In Nov 2019, LK Group held a factory open house to the public. During the event, LK debuted the world’s first DCC6000 for electric vehicle battery cases and car body structural parts manufacturing. The customer, which itself is a well-known manufacturer in the electric vehicle industry, placed an order of 10 machines total. Besides that customer, LK has supplied large-scale die casting units to different famous companies in China.

At the end of the interview, Mr. Liu said, "In the future, new energy vehicles will be on par with traditional internal combustion engine cars. The die casting industry in China will grow steadily due to the development of lightweight car component applications and the demand for die casting parts in the automotive industry. For that, LK Group is well ready for the trend!"